Now as i mentioned, the simple fitting of gauges ended up costing me a bit of money. I should now elaborate. For years now, on both my M84 and the M130 ecu, we have had quite odd and non traditional and linear fuel maps. We had always put it down to the big cams, huge overlap due to the way i have the cams dialled in and excessive porting. Furthermore when the car was taken for long drives, whether it be hard drives or freeway cruising, the car ran a bit rough like it was heatsoaked.

Now i should have known better, as in my line of work, i often see issues with big fuel pumps and standard fuel pressure regulators causing all kinds of issues for light load driving, idle quality etc. Now at first, i wasn't sure if it was the gauge assembly causing me issues, or whether it was actually an issue with my fuel pressure. Several simple tests (ie. with a fuel pressure gauge connected, let the car settle into idle, and remove the vac source from the fuel pressure regulator. when you do this, your fuel pressure should increase. If it doesn't, there is an issue with the fuel reg bypassing enough fuel to control the pressure accurately.)

My car was actually a bit more extreme, i assume that it has a compromised diaphragm, as it wasn't able to keep the correct fuel pressure at full boost, in fact, i would only have 25-30psi higher fuel pressure than the boost pressure (21psi). Why is this an issue?? well, when your injector has been designed to have an effective spray pattern at 45psi of fuel pressure, it often loses that pattern, and kind of spits and splatters when it is given less pressure (like 25-30psi).

Now some of you might say "hang on, he said he had 25-30 psi above the boost pressure, so that is 46-51psi". Yes, but that is where differential pressure comes into play. When the engine has 20psi of boost pressure, you have 20psi of air pressure effectively trying to push the fuel back into the injector, so your 51psi of fuel pressure is only coming out of the injector with 30 psi of effort, and you end up with a terrible spray pattern, which means the fuel doesnt mix with the air effectively, and you have an engine more prone to detonation. This is also known as differential pressure, as it is the difference between the fuel rail pressure and the manifold pressure. It is a dynamic value, and is basically used to check that the fuel system is staying in step with the manifold pressure. I was lucky, particularly at my power level, most likely due to my closed loop knock and wideband fuel control, covering for my ghastly oversite.

Thats where this little guy came in. I bit the bullet, and purchased a v2 turbosmart fpr800. Beautiful, solid unit, and are effective as anything. The V2 units are the only ones you should buy, so if you see units for sale that are V1, don't touch them, as they had some control issues with them (Read RobK's showroom thread for an example.)

To make this unit work, i also purchased a tomei rail adapter, and fitted a motec (honeywell) 250psi pressure sensor into the fuel rail where the cold start injector feed line used to live. I decided that i wanted the fuel pressure to be fed into the ecu for 2 reasons, 1. because the m130 uses a volumetric efficiency fuel model, fuel pressure is a strong part of that model, in the form of differential pressure (explained earlier), and 2. i wanted to setup more safeguards in the car.

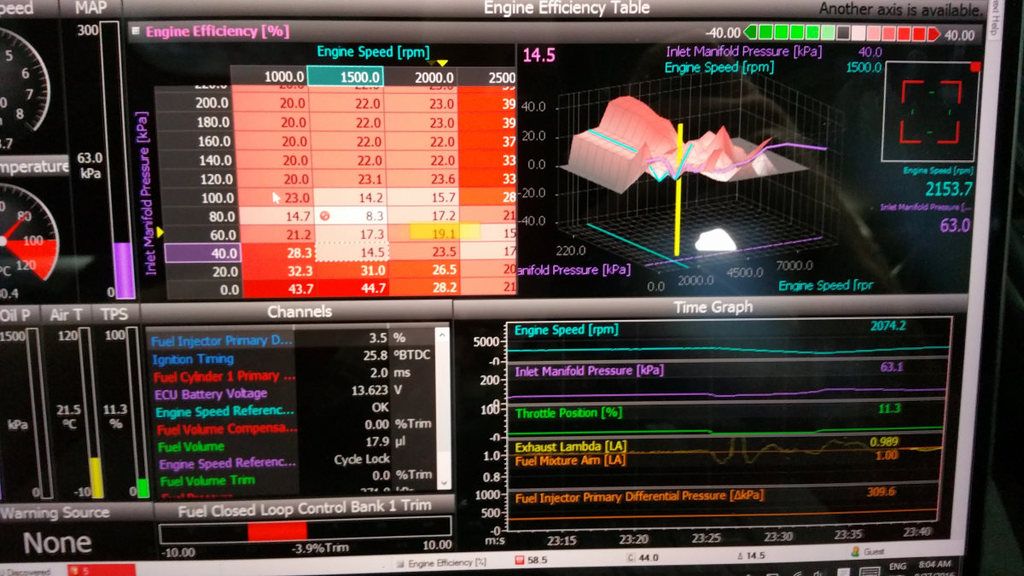

I set the reg up on the drivers side rear strut tower, next to the vent fan. sheerly to keep it a little bit out of sight, and because the car is a bit space poor. Now, I'm sure some of you are wondering, how much difference could the fuel pressure make to the tune? Well in my case, a lot. You will see below a picture of my fuel map that i started to retune set on compare, were you can see the difference in the load sites. As my fuel table is VE, the numbers arent a pulsewidth, or an injection value in milliseconds, but it is a calculated engine efficiency value as a percentage.

As you can see, it was a huge difference. Actually compared to the finished file, it ended up being ridiculous. Now, seeing as I was in for such a drastic retune, i decided to bit the bullet and start toying with some things i had been wanting to try for a while - flex fuel. Due to the mr2's tiny fuel tank, and the fact that the car is a daily driven unit, i didn't ever want a loss of functionality with the car, so i had never tuned it on E85. But since Motec had released firmware with their completed flex fuel model i decided to jump at the opportunity.

Enter the previously mentioned hole in the wallet. New 950cc bosch injectors with all stainless internals, the fuel pressure reg, adapters and a fuel composition sensor. I put everything in the car, setup everything in the engine ecu, and prepared to tune the car. I decided my base map would be on pump fuel, and decided to begin to tune the car. As i was going through my cars gentle paces, i noticed my intake air temp was abnormally high. So i brought the car to a halt, and checked the intercooler setup. Low on water - easy enough to fix, and i had been a touch slack on topping the system up of late. So i began to fill the system up, only to be greeted with the horrid sound of water leaking from the front of the car. Long story short, the water pump in the system had a shaft seal failure, like my last one. now im pretty sure that has to do with my near straight water use in the intercooler system, as coolant is often also a seal lubricant. So my fault, but a really disheartening thing, as it meant i was up for even more money. I tried a reseal of the unit in 2 different methods, but unfortunately both were unsucessful, so i wont go into detail. Enter the new and shiny water pump:

Going with the mantra that got the car to the point that it is now: if it breaks, make it bigger - I went t source a replacement pump. As luck would have it, davis craig have introduced a new, bigger model for the ewp80 - the ewp 130. Improvements include: alloy construction, larger internal passages and a shorter shaft assembly, which im hoping wih the use of coolant additives to help, will be many more years of trouble free motoring. If not, it has a 2 year warranty, and this time the receipt will not be lost.

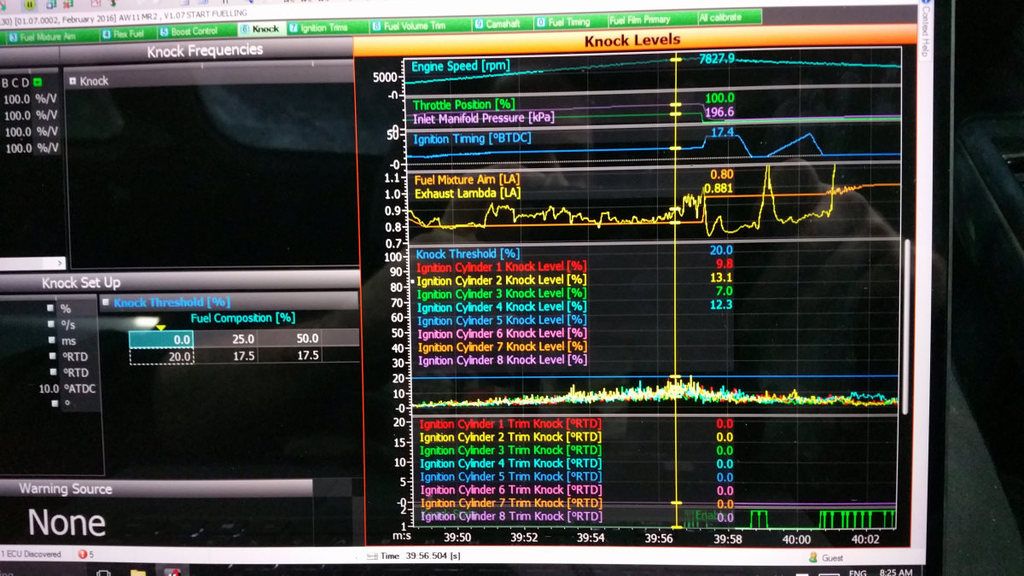

So tuning began, and my knock control again saved my lack of paying attention. Being so sidetracked with everything else, i forgot to guesstomate the top end of the map, and a wastegate pressure pull ended with a massive leanout up top, and the ecu saving the engine from a catastrophic failure.

Now this is the point i hoped I would have an amazing story about a new amazing power figure of tyre shredding glory, but alas, it is not. Between the expense of bearing failure, fuel regs, injectors and the conservativity of pending old age, i decided to turn the car down a touch. I have also noticed that the intercooler is for lack of a better word hopeless. Pressure drop across the core begins to increase exponentially after 15psi of boost. Also the effectiveness of the core is dropping terribly. At 15psi, a 4th gear full throttle run will see the intake temps at 40c. at 17.6psi, they are approaching 60. Now even though i have a massive number of failsafes in place to prevent engine damage, i can't overlook the fact that the cooler is becoming the weakest link. Even though the wondrous charge cooling effects of E85 are plentiful in this setup, it became apparent that if i pushed the car like i once did, i would really be pushing **** a long way up hill. Plus, the car gets driven hard, and when i have enough time one day when im not building other peoples cars, or helping them achieve trophies and p.bs at the track, i will get around to using my car at the track, and i want a useable car, not a hand grenade.

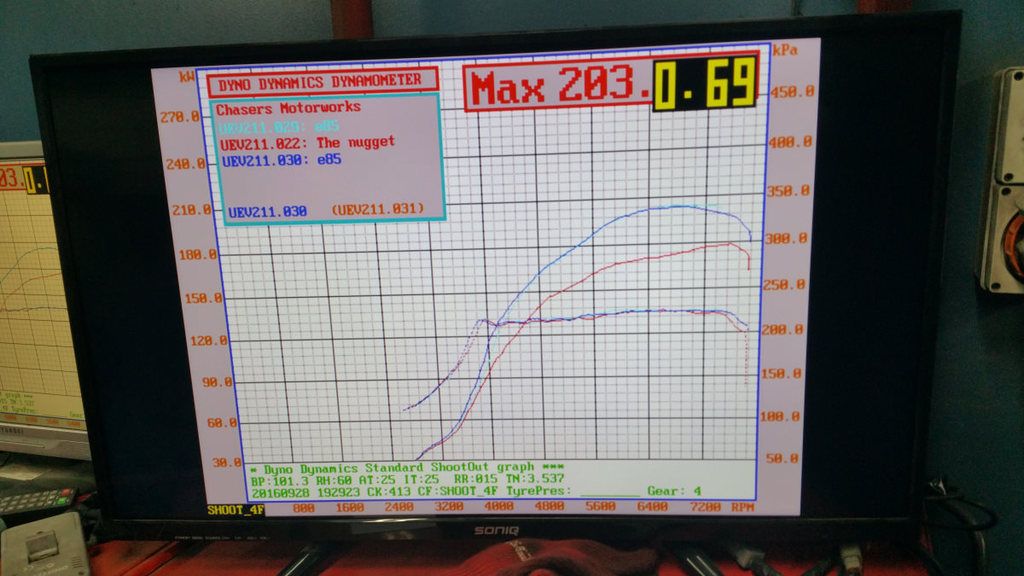

But, everybody loves a dyno graph, so i thought id better leave one here. The darker red line is 180rwkw on 17.6psi of boost on BP 98 fuel. A long way from the old 224rwkw, but it is on 3.4psi less boost, and my 224kw used to be done when united sold 100 octane pump in victoria. The 2 blue lines at the 203kw mark are again on 17.6psi, but on E85. The car took a lot more timing, due to the octane and charge cooling difference that e85 provided. But again, due to the intake temps, i had diminishing gains.

Now before anyone suggests potential issues with the i/c system, yes i know the setup is not perfect. i could put baffles into the end tanks to ensure the core is used effectively, but the system is bled correctly (have several bleed points), i have tested the setup with the flow in both directions through both heat exchangers, and with the data i have collected on all the testing i have done, the conclusion is that the intercooler is too small to be effective in my particular setup. But i'm sure i will cover that in 12 months time when i decided on what way i will tackle the problem, and when the poor piggy bank has recovered. (read: the annual sponsorship payment from the ATO is recieved.)

p.s. some of you with experience with E85 may ask why there is a lack of gain in the turbo response to full boost. It was probably put down to how i loaded the car up on the dyno, as i can report transient response is actually monumentally improved, rolling part throttle i can have 5psi more boost at 3500rpm. It has made the car a lot quicker than the graph would allow you to believe. It is still ultimately slower than when i had 224, but i can live with only 200 for now.