Mechanical diff centre setup explained.

A lot of the time when LSD centres are discussed here on the forum, a lot of the time the are immediately dismissed as they are too harsh, or they chatter and bang when low speed corners are involved.

While they are a touch on the harsh side on a streetcar, many of these diffs are quite adjustable, and the biggest mistake many people make is putting them in out of the box. This is a big no no, as they are set up with maximum preload, lock etc out of the box.

As i had to service and adjust a few centres for cars at work, and took some pics, to give anyone interested a bit of an insight to how they work, and how they can be setup.

Please note the centre pictured is a cusco RS centre, one of the most adjustable japanese mechanical diffs available.

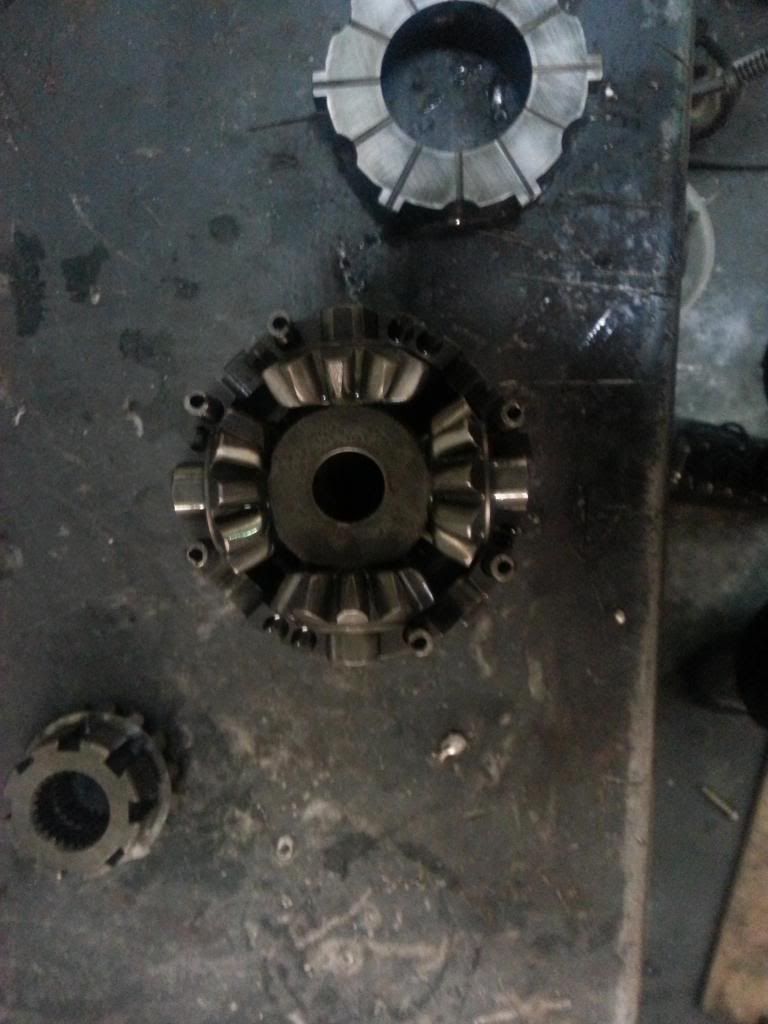

The centre completely pulled down, cleaned, inspected and measured, ready for assembly.

Starting from the middle, we have the housing that holds the spider gears, which sit in the ramps. These ramps take many different shapes, which dictate the ramp up, and whether the diff is a 1 way, 1.5way or 2way.

The centre i was rebuilding at the time was a 1 way, and as you can see from the two pictures, there are two profiles for this centre, the second one being the less aggressive in ramping up to locking the centre. A 1.5way centre will have the deceleration side with a very steep angle, and a two way will have an almost diamond shape.

Next is the preload springs. These are what affect the initial breakaway torque of the lsd, as the more springs fitted, the harder it pushes the two halfs of the housing against the clutch plates.

Here you can see 4 of the possible 12 springs fitted. This is the minimum amount of preload you can realistically run. In the case of this centre, it worked out to around 28nm of initial torque.

This means with the centre assembled and stub axles fitted, with one side locked up,it took 28nm for the other side to 'break free' and freewheel.

A little bit more preload

You can go all the way up past this point. A full set of 12 springs in the centre works out to 89nm of preload. Considering this is a front diff for a 4wd, that would cause way too much understeer when powering out of a corner.

Next up is the clutch packs. These dictate amount of possible lock the centre can provide. You can remove plates, in some centres add plates, and re order them for varying amounts of lock. Above is the 100% lock config, with all the plates alternating. Please note there are two plates removed already from this particular centre, and as this is an early cusco centre, it was only a 10 plate per side diff, not a later 12 plate model.

Now with one of each type paired together, it is now at around 80% lock. This doesn't mean that the centre will not lock up, but it has some compliance and slip available to it.

Again even less lock.

Now assembly begins. ALWAYS apply oil or assembly lube to everything when assembling diff centres.

Ready for the outer casing. A lot of people will actually assemble the centre in the other half of the housing, but i find it a pain to locate the springs doing it the other way.

Nearly done.

Depending on the number of plates etc, bolting the top on can be quite hard, as the plates can protrude 5mm plus, where you will need to clamp it shut with a vice or clamp to put the bolts in. Many on the bolts for holding the top on a M5 bolts, so not properly clamping the housing can cause you to strip those threads.

As this one doesn't have a ring gear bolted to it, the bolts are a lot more industrial.

And there you go, all assembled and ready to go.

I hope that provides some insight into mechanical plate type centres, and puts some consideration for people if purchasing one not to put it in out of the box - were not all drifters. There are is another type that uses cone washers for adjusting preload, like the cusco MZ, ATS carbon and a few other centres but i don't have any pics handy to explain the differences.

For a general note, cone type plate diffs are far more aggressive, and work slightly differently but can provide a greater amount of lock.