Knightrous

MR2 Deity

- Total Posts : 2045

- Scores: 272

- Reward points: 5721

- Joined: 2011/04/07 19:51:15

- Location: .

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2012/12/29 17:21:06

(permalink)

MCT_MR2

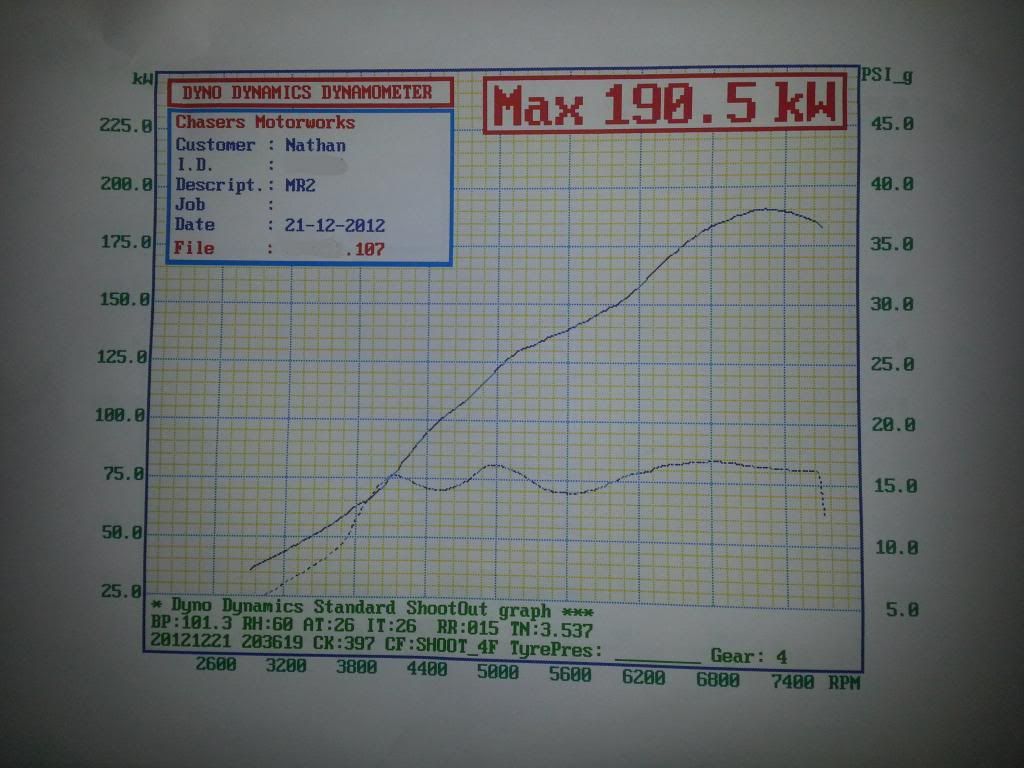

What is up with the boost? Swinging 2-3 psi up and down in the mid range, must be costing you some power/torque through there. Able to get some dyno graphs with the torque curves on them? Keen to see how the torque comes into it all when comparing the SC to the Turbo.

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2012/12/29 22:28:13

(permalink)

the boost swings a bit due to the actuator design on the efr turbos not being the best. we leveled it out, but it overboosted very easily, and 16psi very quickly turns to 20+ on a spike, so it has been left alone for now. When I get a chance to go do another printout I'll do one with torque.

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

kameleon

Supporter

- Total Posts : 2733

- Scores: 106

- Reward points: 6018

- Joined: 2011/04/07 19:51:15

- Location: melbourne vic Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2012/12/31 00:32:56

(permalink)

I think all mechanics can attest to making the customers cars better!

Will have to come for a ride sometime Nath.

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2012/12/31 10:26:56

(permalink)

most definitely trav. also due to driving too many customers cars, this still feels really slow, hence I'm going to try for more midrange. I'll gladly take you for a spin.

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

kameleon

Supporter

- Total Posts : 2733

- Scores: 106

- Reward points: 6018

- Joined: 2011/04/07 19:51:15

- Location: melbourne vic Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2012/12/31 10:52:25

(permalink)

Ah yes driving (or riding which is 100 times worse) dulls the speed senses alot. I hope my MR2 is faster than the Monaro...

The fastest Adub ive been in was Robs 3S version, so it will be good to see what the 4A is like.

|

ZEROGK

MR2 Deity

- Total Posts : 188

- Scores: 85

- Reward points: 2420

- Joined: 2011/04/07 19:51:15

- Location: Melbourne VIC

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2012/12/31 11:20:42

(permalink)

Rob said his car had 185rwkw, but I easily walked him down the straight at Winton. He was having clutch problems as well but I'm pretty sure mine wasn't making anywhere near that much power on that day. Do you know if he ever did a 1/4 mile run?

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/03/29 19:31:29

(permalink)

Wow, i just realised how long it has been since i have done an update, so i'll recap on the last 12 months. Power wise not much has changed, i tweaked the cam positions again and tidied some stuff up, and leaned everything out on cruise a bit more, the boost is a steady 16psi, few hundred rpm better response and it was 197ishkw. I have given the car a bit of a freshen up steering and suspension wise, as it had been woeful for quite a while, i had the dreaded aw11 front end rattle, steering wheel shakes, and massive body roll. So first order of business was the steering and ball joints. I ended up getting roadsafe aftermarket bits through bursons, as it worked out costing me $200 for tie rod ends, rack ends, and ball joints for both sides, which was soooo much cheaper than twos r us it was ridiculous.  Next order of business was struts and springs. My car had tokico struts that came with the car, and fitted with cusco springs, which are 4kg front and 6kg rear. As pretty much everything was hammered (struts, springs im sus on, top hats, rubber spring perch inserts etc), it was cheaper as a mean time option to get a set of BC coilovers. I ended up getting the HC RM model, and they came with swaybar links too. Oddly enough the camber plates for the front end were fitted wrong left to right.   They ride alright. I was concerned at first about the spring rates for a street car and how stiff they ride, but i have to say they really aren't. 8 clicks from full soft gives them a slight bounce over bumps, 12 clicks plus is when they get really firm. I had sussed out several custom options (KW, MCA, and Ohlins) but with quotes starting at $6k, i gave them a miss (id spend that on fixing the body and paint on the car before anything else.) Also to help keep engine bay temps down, as i was having issues with melting some of the older components that inhabit the engine bay (more on that later) I picked up a passengers side engine scoop off ebay. I has made a massive difference to the temps in the bay, im tempted to get the drivers side version that they also sell.

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/03/29 19:49:39

(permalink)

Now one of the main reasons I haven't turned the wick up further on the little mongrel is spark. The setup is still using a standard dizzy, some NGK leads and an MSD blaster coil. One of the last times the car was on the dyno (7 or 8 months ago, before the scoop) we gave the car a run or two at 18.5psi. It looked like we would have netted around 210kw or so, but we had the beginning of ignition breakdown present. I run iridium plus with a .7mm gap, so i was not prepared to gap down the plugs any further (i like my car to idle). I raided my parts bin from my years at toyota and dug up some denso coils from a 1nzfe. Seeing as i still have a spare motor from MK1corse, i decided to start mocking up a setup onas low a budget as possible. I picked up a dizzy blanking cap, and some coilpack connectors from SQ engineering, and one afternoon roughed out a loom for it.  Seeing as this setup required the NA rocker covers (centre plate mounting bolts are in different spots etc), i decided to modify the rocker covers to how i want, seeing as they were from the spare motor. First order was uprated breathers, which i was unlucky enough to get a bad batch of weld on AN fittings (as seen above), so i ended up having to grind them back off, and smoothed out all the lettering while i was at it. Next up was a lick of paint and some heat shield tape to help keep heat out of the rocker cover (so the gaskets last a bit longer)  I had a chance a little while back to fit up the rocker covers and coils, and give the whole lot a test. All was well, but i will have to mess around with the tacho output to get it to work (probably a 12v supply on the output with a pullup resistor, or a tach adapter of some description. Either way, i am still running the car with the dizzy and coil, as i haven't had the time or motivation to finish off the tacho wiring, but it looks pretty good for a slap up job.

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/03/29 20:21:14

(permalink)

Now my car has had a love hate relationship with the bottom shift linkage on my car. It melted early on in the turbo setup, and i was unable to source a replacement. So with some variety of tapes, zipties and heat shielding, it was patched up and some care was taken till i could find a replacement. Fast forward to earlier this week, and after a spirited tailgating of an evo through kinglake, the linkage decided enough was enough, and decided i should get by without gears 2,4 and reverse. So once again i tried to find a replacement, with no luck. To make matters worse the linkage decided it wouldn't play ball with another patch up job (it only gave me reverse back). So i rang around, a company here in melbourne that makes and repairs speedo cables and shift linkages can do it, but can't take on any more work for two weeks hile they catch up. So with nothing to lose, today i pulled out the linkages to size them up. I had a spare set of evo 8MR linkages lying around from a customers car i did a gearbox conversion on. Turns out they were close. Sort of close.. More i decided i was desperated, had time on my hands and would make it fit. Now unfortunately i didn't think to take any before pictures, so i can show you the after with a walkthrough on what it took.  At the shifter assembly end, there was enough length, and the ball end that attaches to the shifter is thankfully threaded with M6x1.0, so this was the easiest end to modify. Slight altering of the shifter base to accommodate the linkage was simple, so then it was a case of measuring it all up, cutting the excess of the evo linkage, tapping a thread into it, and using a turnbuckle nut to join the two. The benefit of this is i have been able to tweak the shifter a little bit further away from me, its pretty much in line with the wheel now, and still has enough throw to engage the gears.  diameters of the cable section are identical, the length between the mounts are a bit different (evo linkages are longer) but not enough that they could not be used.  Now we come to the painful part. the end is the same diameter, but the mr2 ones taper down to slide through there mount, whereas evo ones clip into the frame. The solution? I had to take 4mm off the diameter of the mount to allow it to work with the standard linkage bracket. Now due to what i had available to me (a bench grinder, a right angle prep tool, some sandpaper and a file) this is a little bit rougher than i would like, and it also took about 2.5hrs for this step alone. I can't say i ever want to do it again, but it is a snug fit, the clip holds it tight, so im happy.  Now the linkage was still around 35mm too long to fit correctly, so i measured it up, cut a section out and welded it back together. I also fitted a set of speed source shift bushes that have been living in the bottom of my toolbox for about 5 years now. They are a perfect fit in the evo linkage.  Then some heat shielding and ready to fit. I also fitted the brass bush to the other linkage.  I added some lockwire at the gearshift end for a bit of security, just in case (the retaining clip is fitted from the bottom, and it holds the linkage firm, but not rock solid).  And back together. My gearshift boot was quite ratty, so i deleted it, and gave the shift plate a quick hit of paint.  Now call me ignorant, but i finally remembered to clean my headlight lenses and realised they are made of plastic, which isn't uncommon for jap imports, but usually not from the 80's, and also that it has MR in the middle. Are these aftermarket? Anybody know??

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

ZEROGK

MR2 Deity

- Total Posts : 188

- Scores: 85

- Reward points: 2420

- Joined: 2011/04/07 19:51:15

- Location: Melbourne VIC

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/03/30 12:05:40

(permalink)

Mad update! MCT_MR2I run iridium plus with a .7mm gap, so i was not prepared to gap down the plugs any further (i like my car to idle). (boring question) Would you recommend using Iridiums over the standard BKR7? I always thought copper was best as long you change them on a regular basis. I'm using Ford edis coils btw MCT_MR2...and one afternoon roughed out a loom for it. LOL still looks better than anything I could make in 1000years! MCT_MR2Are these aftermarket? Anybody know?? TYC is an aftermarket Taiwanese company that makes cheap OEM replacements for headlights/taillights/etc. Still I'm surprised that they are plastic lenses

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/03/30 12:25:59

(permalink)

Iridiums are a bit better in as much as they concerntrate the spark a bit better, so you don't blow the spark out as quick, and you can get away with fouling them a bit more and still have strong spark.

Some ignition setups arent hugely fond of iridium plugs, but the main reason I run them is that are what we stock for the most part.

Yeah, it makes sense that they are taiwanese lenses, when they are clean they are way too bright, and they dont quite diffuse the light properly.

As for the compressor surge I mentioned on your thread, I have a few more things to try. I know if I squeeze it on, it doesn't really do it, and I might pick up a turbosmart recirc valve and see if it is better or worse.

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/06/01 20:07:21

(permalink)

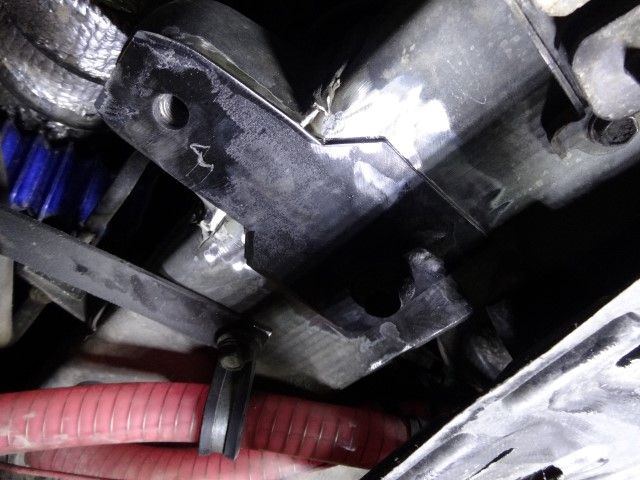

Right, time for a bit of a carnage update (it's been a while since i properly broke something) Coming back from a mates house in King Lake yesterday, i wasn't doing anything out of the ordinary, but after crossing the lovely railway tracks on donnybrook road, something didn't feel right, there were some ungodly noises coming from behind my seat on acceleration and deceleration (i though i smashed another cv shaft) so i limped the car home. Today i went to work, jacked the car up properly and found that the front torque mount had halfway ripped out of the chassis rail.   Now i heard of it happening to track cars, high powered cars and people that like to launch their cars and had seen various repairs on the interwebs over the year, a lot of people patching the area with 1/4 inch plate and upgrading the bolt sizes to M12. I was not a fan of this idea, as A. it was more work than i had time for, and B. 6mm steel plate is waaaaay overkill, considering the fact that you are welding it to 16g sheet metal. So step one, i did some CAD (carboard aided design) to make a template of my patch panel. I cut it out of 3mm steel plate, and cut the holes out for the front mount bolts. I completely seam welded the nutsert in, as i have no faith in tack welds.  I then cleaned up the area in preparation for welding, and cut, drilled out the spot welds on the tab of metal and chiseled it off.  I checked the fit of my patch panel, which was now cooled down enough to touch  Bolted it in at the back, and welded it in, doing one inch passes at different parts of the piece, and allowing time to cool, so it didn't set the car on fire, or warp too much so that the mount would not go back in.  I can't say i ever want to tig weld upside down, laying directly under what im welding with a non auto darkening mask EVER again. Thankfully i only lightly burnt myself once with some stray molten filler rod. I let it cool down, gave it a quick etch prime and hit of matte black paint, and bolted everything up.  I fitted up some nord lock washers for the bolt that passes through the mount, as it appears that it may have been sliding due to the slotted bolt holes. I thought of boxing up the front mount before bolting it up, but i didn't really have time to muck about, and i think id rather let the mount bend rather than pull a larger section of the chassis out. Now some of you may have noticed the fact that i left 2 small gaps in my welds, where the seperate nub and the main chassis member join. I did this for two reasons, first off all i didn't want to weld the entire way around, as that leaves no room for any give whatsoever, which would make it easier to crack (that is why chassis' are stitch welded for strength, and not seam welded. Secondly was because the nub is a seperate spot welded piece, i feared if the wasn't some allowance for so give in my patch panel, i would end up tearing that off. In other news i have got the cop setup up and running, but have had no time to get it on a dyno. I might hold off for now, and wait till i get around to doing my flex fuel setup, but i'm really bored with the power, so we will see what happens.

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

robk

MR2 Deity

- Total Posts : 2172

- Scores: 314

- Reward points: 5229

- Joined: 2011/04/07 19:51:15

- Location: Sydney / Central Coast, NSW Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/06/01 20:41:48

(permalink)

Well done with the welding in that awkward location!

Have you got the tacho working yet? In case you haven't, here is how I did it on my SW20, with perfect results:

- Aux output from my aftermarket ECU, configured as a tacho output and wired to the factory tacho wire (with the factory igniter removed).

- Instead of a pull-up resistor to 12V, I have a pull-up relay coil to 12V (the contacts of the relay are unused).

- The relay coil generates a voltage spike on each tacho pulse, just like the factory tacho signal which comes from the ignition coil negative in the factory igniter.

I know you have an adub not an sdub, but I'm assuming that they have a similar tacho signal/setup.

|

MCT_MR2

MR2 Deity

- Total Posts : 626

- Scores: 104

- Reward points: 4232

- Joined: 2011/04/07 19:51:15

- Location: Melbourne Victoria Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/06/01 20:56:28

(permalink)

robk

Well done with the welding in that awkward location!

Have you got the tacho working yet? In case you haven't, here is how I did it on my SW20, with perfect results:

- Aux output from my aftermarket ECU, configured as a tacho output and wired to the factory tacho wire (with the factory igniter removed).

- Instead of a pull-up resistor to 12V, I have a pull-up relay coil to 12V (the contacts of the relay are unused).

- The relay coil generates a voltage spike on each tacho pulse, just like the factory tacho signal which comes from the ignition coil negative in the factory igniter.

I know you have an adub not an sdub, but I'm assuming that they have a similar tacho signal/setup.

Your either a psychic, or you spent too much time at adaptronic doing tech support with things like assisting on people trying to get tacho's to run. Yes, they are same being negatively driven. I was actually optimistic, and tried using a 1k pullup resistor to begin with, which as you can imagine didn't work. I even went as far as pulling the cluster out, as putting a 10k resistor in parallel with the 30k ballast resistor to see if that would help things, and also make it easier for the tacho to keep up - no dice. I have a relay base wired up and ready to go on one of my aux outputs, but i dug through the shop and we only had dioded and relays with resistors across the trigger pins, both of which would not allow the spike to fire the tacho. I'm assuming it was you that disliked my post in regards to the wavy boost control, that was when we first set it up in open loop, and the actuator was and a less than perfect angle to operate on. I have since fine tuned the pre load and open loop duty cycles, and it holds a flat 16psi, for 197rwkw. When i get around to the flexfuel setup, apart from switching to closed loop boost control, i will be doing ethanol content based target boost (only as a percentage gain), and also will aim to setup a throttle based aim table, as for whatever reason, the turbo surges unbeleivably at lower throttle inputs (zeroGK has the same issue), and when i bump it up to around 20psi, i think it will help drive ability on the little 195 rear tyres.

'88 MR2 4AGTE W/ EFR6258 224.6KW @ 20PSI more to come......

|

robk

MR2 Deity

- Total Posts : 2172

- Scores: 314

- Reward points: 5229

- Joined: 2011/04/07 19:51:15

- Location: Sydney / Central Coast, NSW Australia

- Status: offline

RE: MCT's AW11 ....... 100RWKW on run in tune!

2014/06/01 21:12:58

(permalink)

I did indeed learn the tacho trick at Adaptronic haha.

It wasn't me who gave the thumbs down to your previous post, I totally understand why you had the wavy boost curve.

I'm keen to see how you go with flex fuel. I'm loving it on my car!

|