Flywheel - Rim Weight Reduction

I'm looking to do a bit of weight reduction on the stock Toyota 1MZFE flywheel I have, which weighs a lot.

I've seen plenty advise to not lighten cast steel flywheels as it might cause the flywheel to develop a crack and/or shatter. Now from the research I had done into this previous, this was generally caused by doing weight reduction on flywheels using the skimming method, where you take some "excess" casting off the back side of the flywheel and neaten up the flywheels profile.

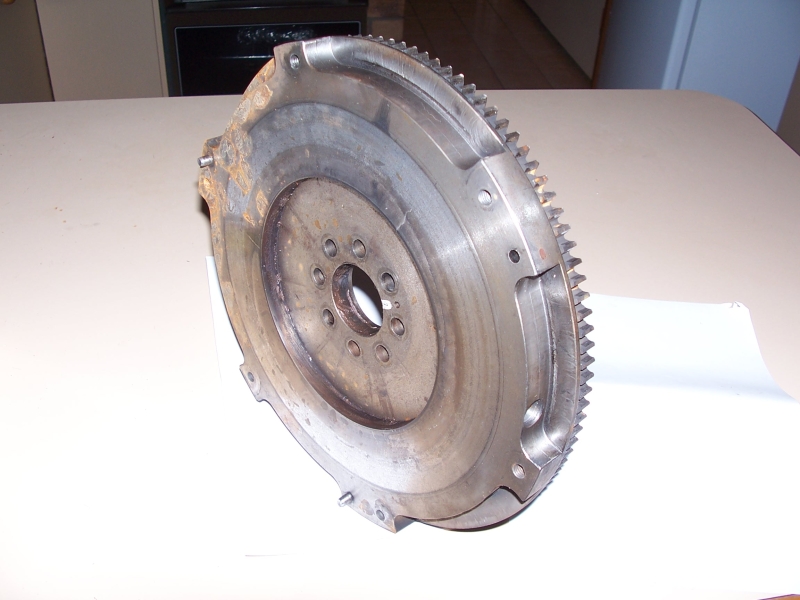

Like this flywheel.

However I cannot find much information on why you shouldn't do the weight reduction on the outer rim of the flywheel, like this flywheel.

From my guestimation and mengineering skills, the outer rim is where the most weight savings are and the least amount of material used for structural integrity of the flywheel itself. This should be safe to CNC mill off and then re-balance, but I wanted to see if anyone else has done something similar or worked with someone who has done it.

I'd love to just drop $500 on a Fidanza 4kg 1MZFE flywheel, but $500 is a lot of cash I could drop on something better (getting the conversion finished!).