Finally some more progress!

Lots of small things have happened in the last week or so, and there is a possibility that I'll be able to start setting up the Adaptronic e1280s ECU and start the car before the end of the week

fingers crossed!

The following has been completed since my last update:

- New spark plug leads fitted

- Filler neck fitted for W2A system

- Oil catch can fitted

- BOV fitted

- Pod filter fitted

- New custom harmonic balancer fitted

- 3 bar MAP sensor fitted

- Fuel pressure regulator fitted and plumbed in

- Boost control solenoid fitted and plumbed in

- A/C compressor re-fitted

- X-brace re-painted in black (not fitted yet)

- Most hose clamps fitted (happy Surok?)

All that's left is for me to wire up the pump/fans/sensors for the W2A system (not vital to start the car of course), and there may be a few very small things for my mechanic to finish too.

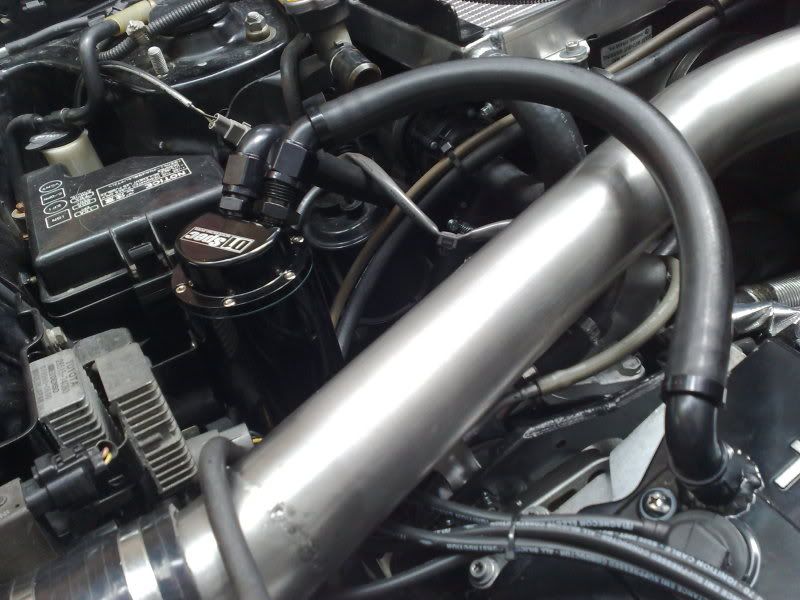

'D1 Spec' oil catch can:

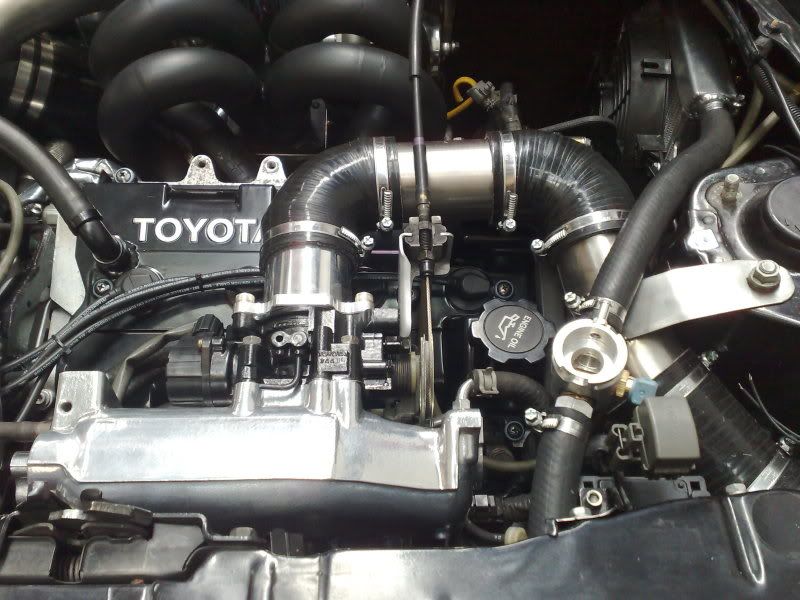

MSD 3 bar MAP sensor in place of stock MAP sensor, and filler neck for W2A IC system (notice the water temperature sensor which was custom fitted):

External wastegate plumbing:

MAC boost control solenoid valve:

Turbosmart fuel pressure regulator:

Turbosmart plumb-back BOV (the BOV itself isn't really visible, but you can see how it plumbs back very neatly):

Big intake pipe/hose from pod filter:

Looking up into left side vent, showing the pod filter location:

This one is just to show what I mean when I say that I get to watch the progress very closely every day while I'm at work (that's my office window on the second level of the building, with my car on the hoist

: