5SGTE, I'm not sure how Pat has plumbed his unit, but i can help shed some light if you like.

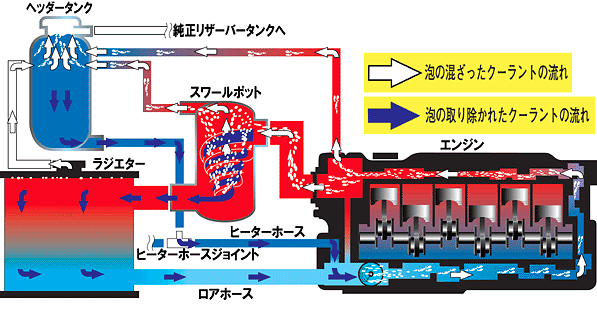

Here is the basic system diagram from when billion/arc used to sell universal swirl pot kits.

This is the swirl pot. it goes in the upper radiator hose. it is just a basic cylinder with offset radiator hose outlets opposite eachother, to get a swirl happening. This helps the air get bleed port, which is attached to the header tank.

Then you have your header tank. This becomes both your pressure cap, and highest point in the system. You will have take off points to the swirl pot, lower radiator hose (engine bay one in an mr2), and you can also take off from heater hose points or other trouble areas if you wish.

In my experience, i have found them highly effective if circuit vehicles. for an example, we have a shop evo, that we shift at 8800rpm. The standard evo water pump starts to cavitate at 8000rpm, and even with the system pressure bumped up to 1.5 bar, the system will still cavitate at around 8300rpm. the caviation would cause localised boiling, which would introduce air into the system. also pockets have normal areas that are hard to bleed. The header tank system allows the air to be better managed, and removed from the system during hard running.

Unfortunantley the ARC and billion kits are discontinued, but you could probably find an alternative, or have the bits required made up fairly cheaply. I have some rough pics of them installed on our shop car, where you can get an idea of an example of how the system can be setup: