Did a few things recently on the Gen3.

Realised that the Gen3 was non abs, so had the abs rings swapped over on the half shafts, this was easily done by a CV repair shop and very cheap.

The drivers half shaft was difficult to remove as the bearing was seized up in the carrier thats bolted to the gearbox. Had to unbolt the carrier and pull it out with the shaft.

Took off the old timing belt etc and replaced the cam seals and front crank seal. Bought a cheapo Ozito electric impact wrench to undo the front crank bolt, it did it easy. The grunt this thing has is amazing (300NM apparently), especially for the cheap price ~$70. Should have bought it at the start, would have saved a fair bit of time and grunting. Wonder if it would have unbolted the half shaft bolts??

Used a bit of pvc pipe (with another layer glued on the outside for added thickness) and the cam gear bolt to press the seals in, made it very easy as i dint have socket big enough. Had to replace the cam seals again (as a precaution) as the bearing cap edge sliced a very thin layer of rubber off the outside of the seal as they pushed in. I chamfered this very sharp edge of the bearing cap lightly and the seals went in easy after that.

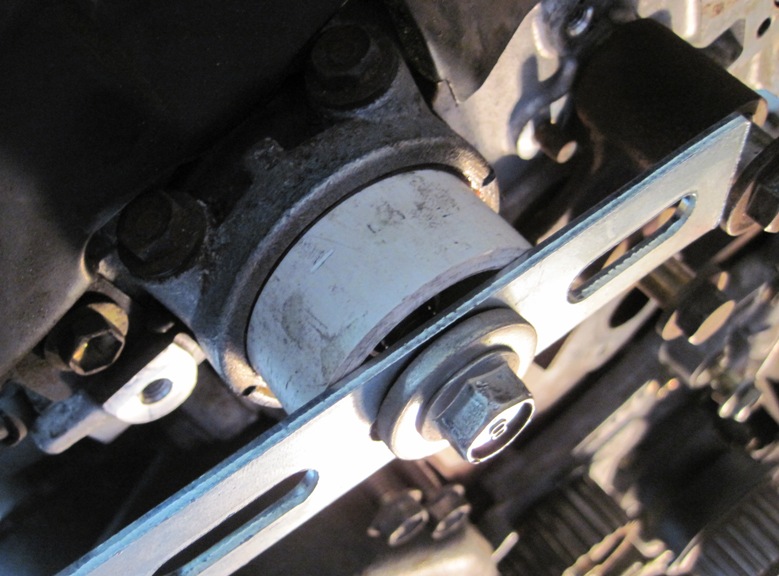

Pressing in cam seal:

Used a piece of plastic and the timing belt pulley and harmonic balancer bolt in a similar way to insert the front crank seal.

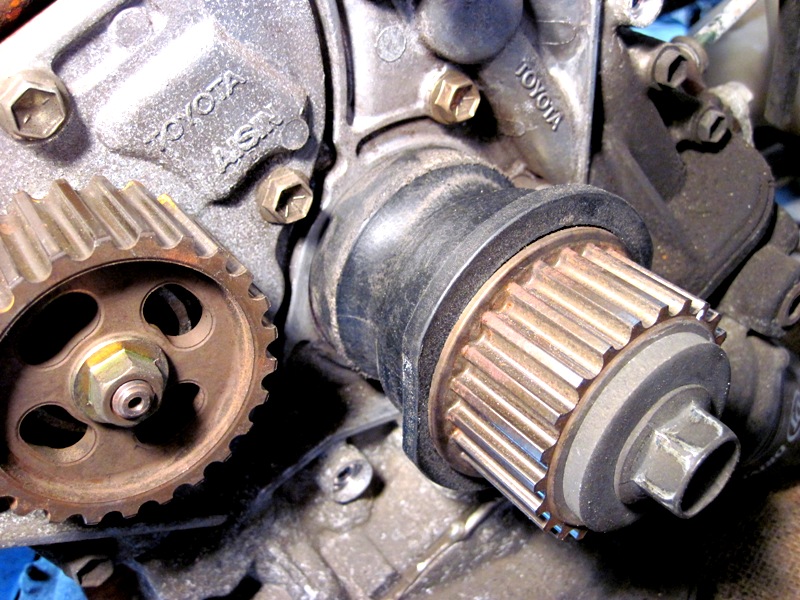

Front crank install:

Got a new water pump and timing belt idler pulleys still need to install and then install new cam belt. Will also test the thermostat to check opening temp is ok and to make sure it opens fully.

Had a quick play with the thermostat housing this afternoon to try and see how it would look with a quick freshen up. Used a wire brush to clean it up, then the sissal polish wheel with grey paste, then buff wheel with white paste. spent 10/15 minutes total. No where near the finish achievable, can still see a heap of casting/wire brush marks etc, but for the time spent, i think its a pretty good improvement.

Before:

After:

Trying to figure out what other bits to freshen up. Will definitely spruce up the rocker cover though.

A big thanks to everyone for their input and help with all my questions, much appreciated.

Cheers