Build Update 15.2.2016

Progress on the project has been slow with other work priorities. I had some time to over the last few days to work on the shifter and driveshaft solution

Shifter

Alot of the guys in the US have been using the Toyota MR-S shifter box and cables with the innovative shift linkage adaptor. I found it quite hard to locate these MR-S shifter box and cables and we had a few issue with invetory delay with innovative, so one of my customer who is also building a mid rear engine set-up, suggested the mini copper shifter box.

Surely enough, he lend me his Mini cooper Shifter box and ive measure up the length needed for custom shifter cables to be made. I left this job to Conwire in Milperra and should have this back this week

Driveshaft

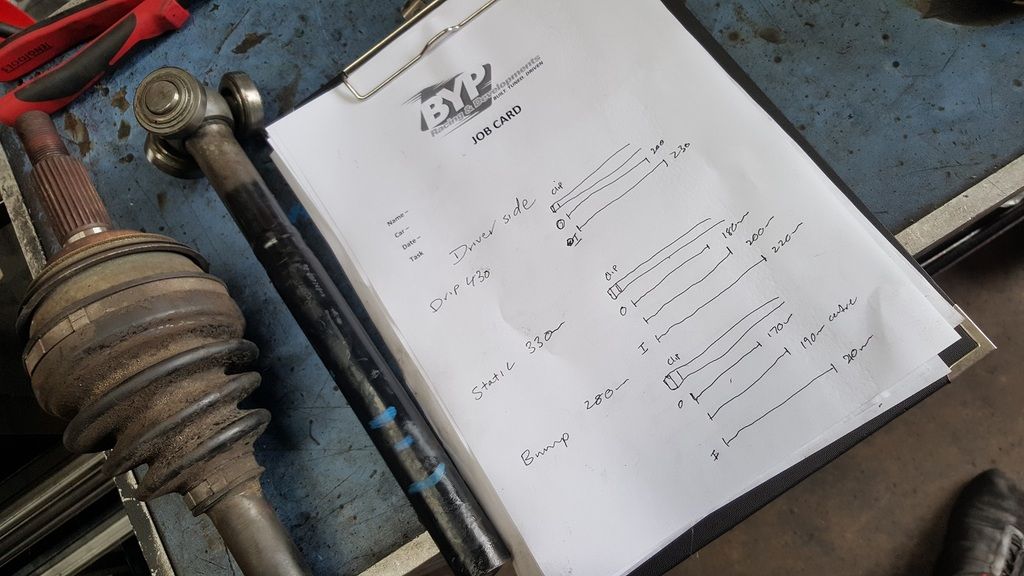

In terms of driveshaft, Driveshaft shop makes there level 5.9 range but its priced at $1899US. It will be a little over $3000 AUD to get it over here which is a quite substantial to the build cost. For the present time, i decided to measure the driveshaft length i need by using the Honda inner and Toyota MR2 outer

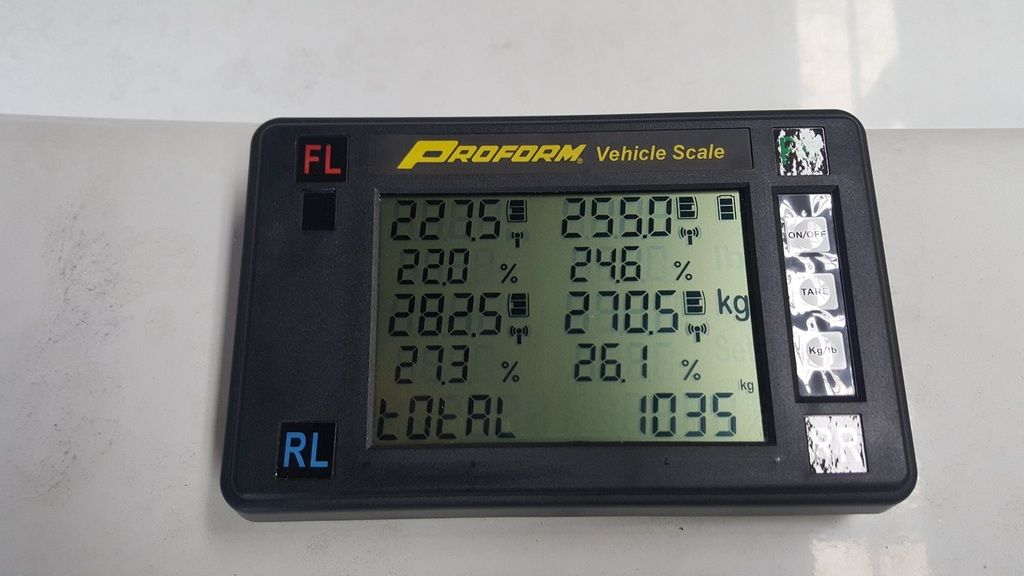

Our new corner weight machine arrived earlier in the week. I put the MR2 on the scale with the K-swap and it came in at 1035kg. This is without axle, exhaust system and fluids. In N/A form, i expect it to be sub 1100kg in street trim.

Being the Australian Distributor of GAB suspension, we will be fitting the GAB SS range to this project MR2 as well

I should have both the shifter and drive shaft solution in 2 weeks.