Right, time for a bit of a carnage update (it's been a while since i properly broke something)

Coming back from a mates house in King Lake yesterday, i wasn't doing anything out of the ordinary, but after crossing the lovely railway tracks on donnybrook road, something didn't feel right, there were some ungodly noises coming from behind my seat on acceleration and deceleration (i though i smashed another cv shaft) so i limped the car home.

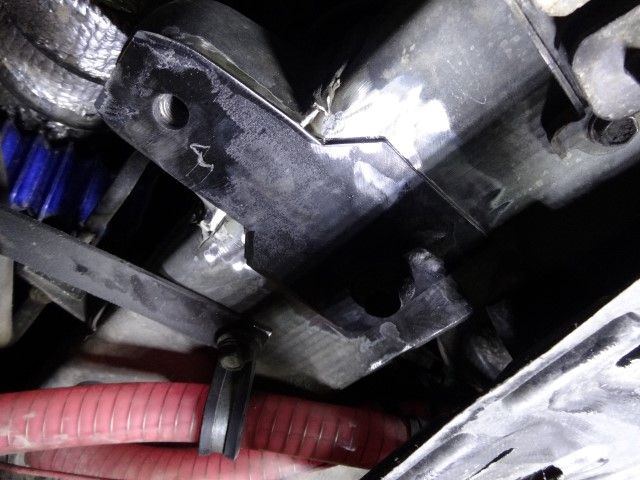

Today i went to work, jacked the car up properly and found that the front torque mount had halfway ripped out of the chassis rail.

Now i heard of it happening to track cars, high powered cars and people that like to launch their cars and had seen various repairs on the interwebs over the year, a lot of people patching the area with 1/4 inch plate and upgrading the bolt sizes to M12. I was not a fan of this idea, as A. it was more work than i had time for, and B. 6mm steel plate is waaaaay overkill, considering the fact that you are welding it to 16g sheet metal.

So step one, i did some CAD (carboard aided design) to make a template of my patch panel. I cut it out of 3mm steel plate, and cut the holes out for the front mount bolts. I completely seam welded the nutsert in, as i have no faith in tack welds.

I then cleaned up the area in preparation for welding, and cut, drilled out the spot welds on the tab of metal and chiseled it off.

I checked the fit of my patch panel, which was now cooled down enough to touch

Bolted it in at the back, and welded it in, doing one inch passes at different parts of the piece, and allowing time to cool, so it didn't set the car on fire, or warp too much so that the mount would not go back in.

I can't say i ever want to tig weld upside down, laying directly under what im welding with a non auto darkening mask EVER again. Thankfully i only lightly burnt myself once with some stray molten filler rod.

I let it cool down, gave it a quick etch prime and hit of matte black paint, and bolted everything up.

I fitted up some nord lock washers for the bolt that passes through the mount, as it appears that it may have been sliding due to the slotted bolt holes.

I thought of boxing up the front mount before bolting it up, but i didn't really have time to muck about, and i think id rather let the mount bend rather than pull a larger section of the chassis out.

Now some of you may have noticed the fact that i left 2 small gaps in my welds, where the seperate nub and the main chassis member join. I did this for two reasons, first off all i didn't want to weld the entire way around, as that leaves no room for any give whatsoever, which would make it easier to crack (that is why chassis' are stitch welded for strength, and not seam welded. Secondly was because the nub is a seperate spot welded piece, i feared if the wasn't some allowance for so give in my patch panel, i would end up tearing that off.

In other news i have got the cop setup up and running, but have had no time to get it on a dyno. I might hold off for now, and wait till i get around to doing my flex fuel setup, but i'm really bored with the power, so we will see what happens.