I have a bit of time free, so i thought id add some more details of the reassembly. Unfortunantley my camera went flat part of the way through, so i apologize for some pics being done with a camera phone.

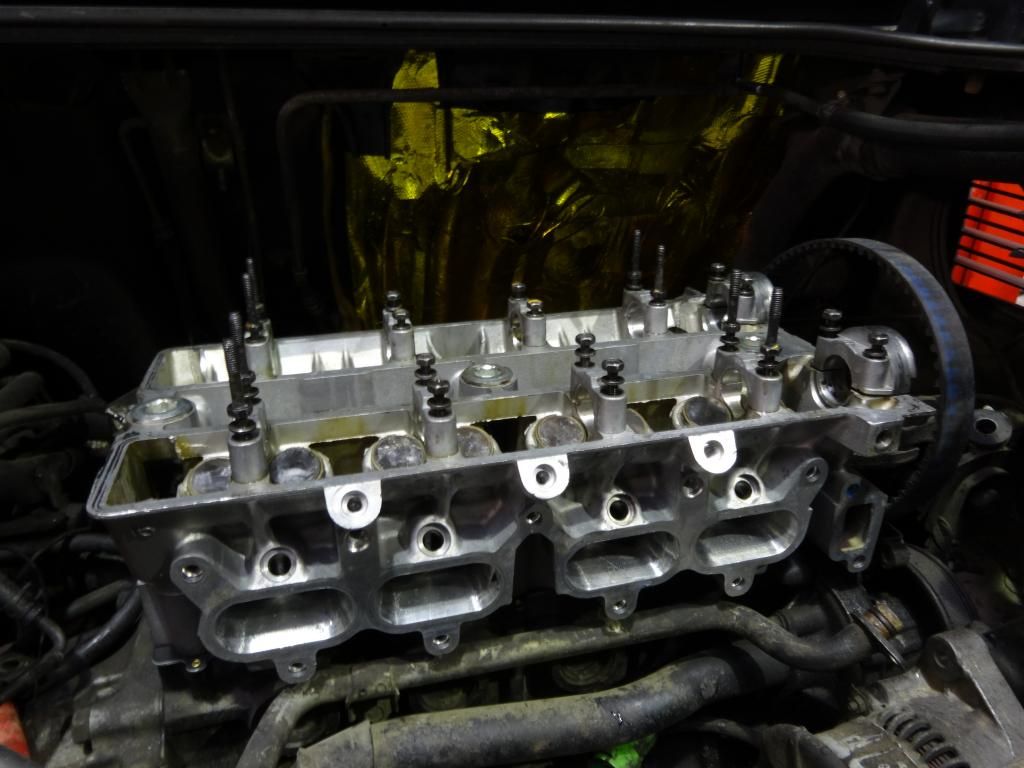

Head gasket fitted, and checked all the head studs were not loose in prep for torquing everything down.

Head was fitted, arp fastener paste was used and the head was bolted back down to torque specs, following the toyota pattern in 3 torque specs (25ft/lb, 45ft/lb and then 65ft/lb) and i personally do 3 passes at each torque spec. You can get away with 2 passes, but i recommend against doing one pass, as you will find that the head won't pull down evenly, as the centre will be loose by the time you get to each end of the head.

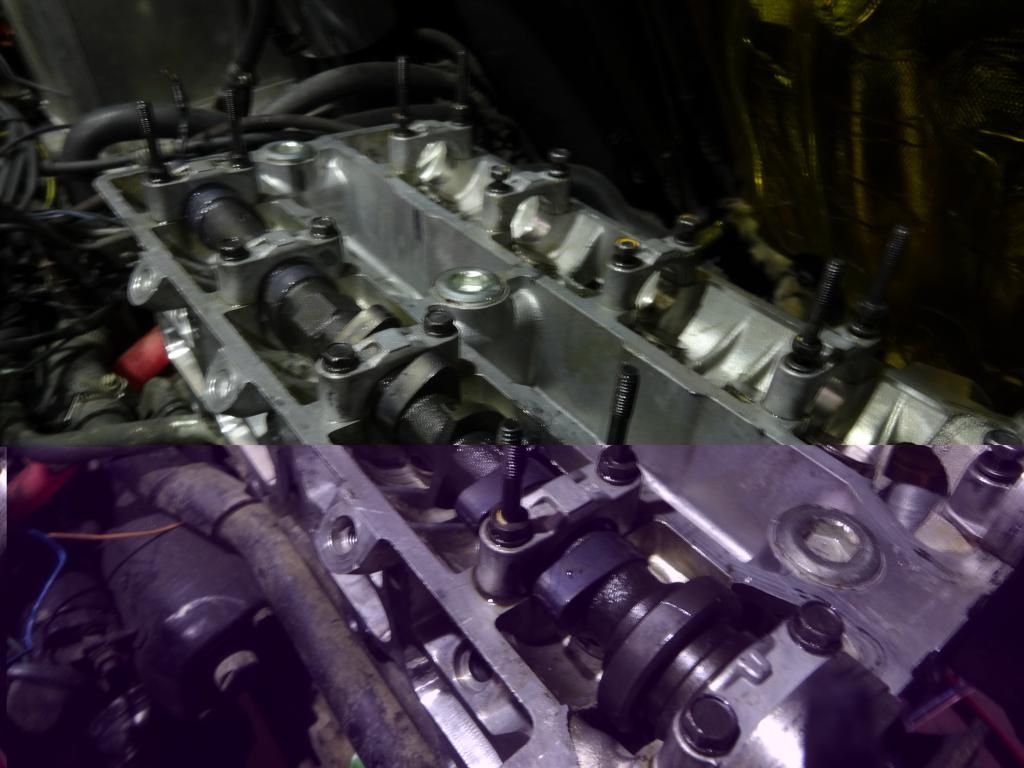

Cams went back in and valve clearances were checked after the new timing belt was fitted. Which brings me to my next little gem....

The tensioner bearing had failed, but was still bolted on tight (yes, a genuine tensioner bearing that was about 3 years and 25,000km old.) When it allowed the exhaust cam to jump, the valves locked up against the piston and the crank gear ate half the teeth off the gates race timing belt.

I also fitted some DEI gold heat sheet to replace the rather tired fibreglass mat that toyota fitted to the firewall from factory.

Things went together pretty quick after that.

I made up new oil lines while i was at it, as the old ones were lightly damaged when the front mount failed. The intake pipe also got the gold treatment.

The turbo oil drain i changed to fuller flow fittings, and all the oil lines are clamped together with billet clamps, and they are insulated with heater hose, as the clamps are slightly too big. Funnily enough you can buy ones that are loose or too tight, but not the right fit.

I also made up a new fuel feed line while i had a chance. Apart from the factory one having only 1/4 inch diameter in places and a lot of bends, i wanted to delete all the banjo bolts and the fuel pulsation damper. The new line is made out of SAE30R9 grade fuel hose for those interested, it has a synthetic liner in it, is safe for use with ethanol, bio diesel and a host of other non rubber friendly hose, for those that are thinking about going to e85. I used full flow push lock fittings, and heat sleeved it, as the line comes close to a lot of coolant hoses.

Thats where my photos end. I upgraded to a 2l catch can, as my old one had lines that were too small, the volume of it was to small, and it had been around for many years. Going up to 2l makes it cams compliant if i ever compete in a cams event with the car.

I will finish up all my checks and bits and pieces, and get it back on the dyno during the week. A fair bit has changed since it was last tuned, if i feel confident with everything, i might turn the boost up 1 or 2 psi and aim to get up to around the 220rwkw mark for now, until i flex fuel it. I know it sounds stupid, but at 197rwkw, it puts down all the power quite well, only rough, bumpy and dusty surfaces cause wheelspin (the rain is a joke, but you have to be an idiot to try and use all the power in the rain), and as it puts the power down really easily, i have started to lose respect for it, punching out of corners and getting on the throttle really early. I need it to have a bit more trouble with traction to make me respect it a bit more.